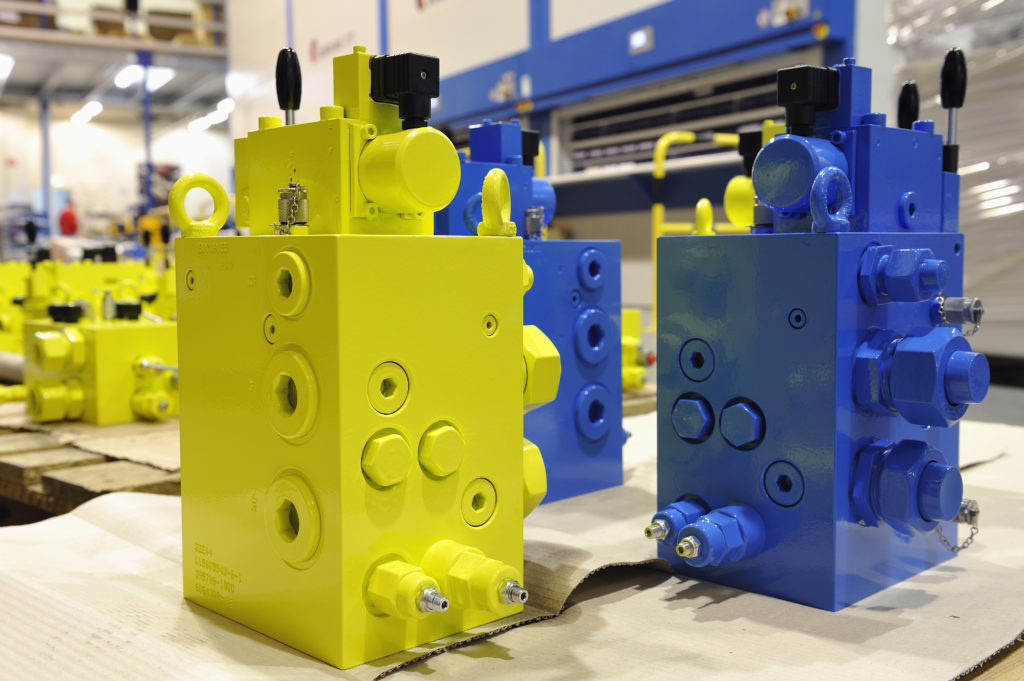

More and more companies apply manifold technology with screw-in cartridges and built on components for their hydraulic systems.

Manifolds can be used for a compact and complete hydraulic control system or as modules for a number of specific functions. These function blocks are usually directly built on to a pump, motor or cylinder. In addition to ease of assembly, manifolds require little space and the risk of leakage and hose breakage is reduced to a minimum. The ongoing developments in the area of cartridge design are continuing to accelerate. Proportional pressure-control and flow-control valves with the accompanying electronic controls are already available.

Advantages

Compared to a hydraulic system with loose components the application of manifold technique (combined with the other possibilities of Koppen & Lethem) offers you many advantages:

- Reduced space requirement because of compact construction.

- Significantly reduced risk of leakage, therefore less pollution!

- Less weight because of the application of light materials, which makes it particularly interesting for mobile applications.

- Reduced cost due to the absence of jointing materials, pipe work and the application of pattern valves.

- Quick adjustment due to modular assembly.

- Simple ‘fault finding’ and service. Dependent on the pressure requirement manifolds are available in aluminium, cast iron or steel.